Ningbo Golden Plastic Industry Co., Ltd.

The company's main business items: injection molding and finished product assembly of high-precision plastic molds for automotive interior and exterior trims, tools, electronics and electrical appliances.

product category

about gangtend

Ningbo Golden Plastic Industry Co., Ltd. is established since 1998 and is located in the Ningbo Beilun High Precision Mold Industrial Park. We specialized in making precision mold and plastic component.

Ningbo Golden Plastic Industry Co., Ltd. is equipped with a complete CAD/CAM/CAE systems which are fully networked with UG, Mastercam, Powermill and etc. We have strong team members in engineering design, manufacturing and management. We have long experience to deal with US, Germany, Italy, Japan, Australia and etc. The factory already accredited with IS/TS16949:2009.

Automotive interior and exterior parts, tools

Electronic appliances

Manufacturing of high-precision plastic molds

Product injection and finished product assembly

products center

The company has cultivated a qualified quality management team and successfully passed the iso/ts16949:2009 quality management system certification

The company's design and R&D team has rich mold design experience and design concepts, and has modern technology to meet customer needs

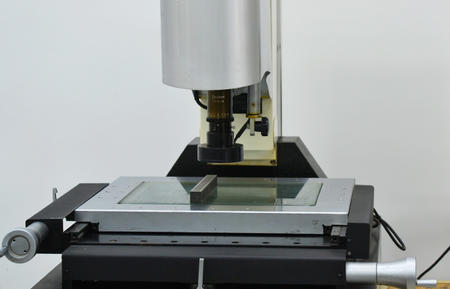

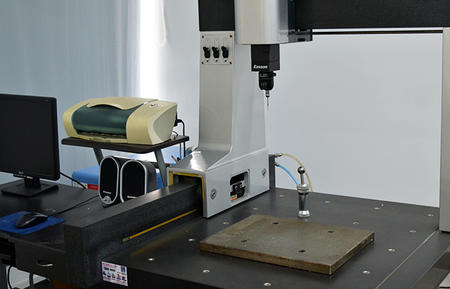

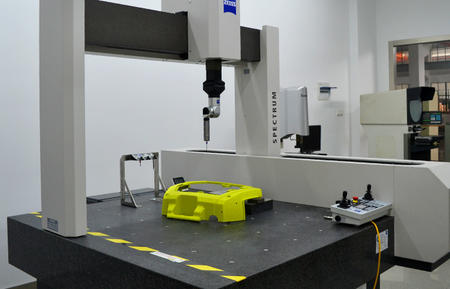

Introduced advanced makino mirror spark machine, large spark machine, middle wire cutting machine, large wire cutting machine

Smooth logistics route design, to ensure the consistency of the material account card, follow the item positioning management and the first-in first-out principle

The company has more than 20 injection molding machines of various models from 100T to 1000T, mold trial and injection molding production is more convenient and faster, strict quality control system and excellent craftsmen provide the necessary quality assurance for our mold and injection molding production capacity.

The company has a team of energetic mold engineers, rich experience in mold making, dedicated to work, team spirit and sense of responsibility. For the production of mold matching, the company has introduced 100T and 250T high-precision mold clamping equipment to improve mold production efficiency.

The company has cultivated a qualified quality management team and successfully passed the ISO/TS16949:2009 quality management system certification. Quality control follows the principle of full participation. The improvement of employees’ quality awareness and quality control skills training are the focus of the company’s management work.

The company's design and R&D team has rich mold design experience and design concepts, and can customize molds according to the needs of customers' products, so as to provide customers with more suitable and more humane solutions and guarantee the quality of molds.